E-axles for EVs and hybrids

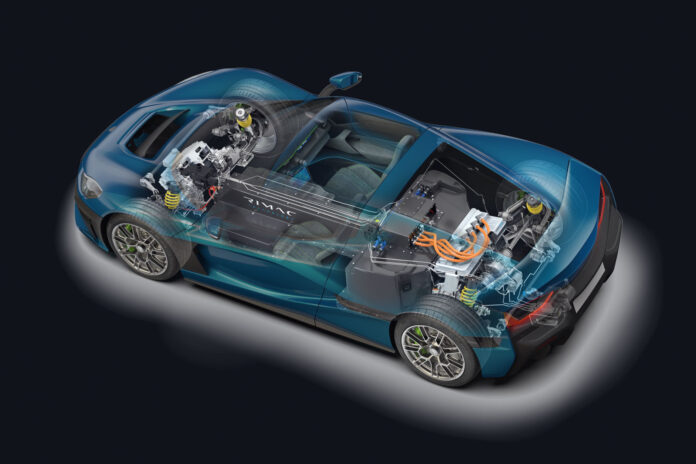

The new e-axles, which combine electric drive motors, gearboxes and control electronics in a variety of light and compact packages, can put out between 200bhp and 470bhp in layouts to suit front-wheel drive, rear-wheel drive and four-wheel drive. Pitarevic also stresses the units’ suitability to both hybrids and pure EVs, and cites BMW, Porsche and Saudi Arabian EV start-up CEER as customers so far – as well as many others that remain anonymous.

This all comes as Rimac prepares its new €300 million (£261m) manufacturing campus, comprising 95,000m2 of production space in Zagreb, Croatia, to create tens of thousands of these tech components every month.

Explaining how quickly e-axle tech is changing, Pitarevic pointed to a number of examples. One was an assembly more or less equal in power and torque to the 1288bhp Nevera’s rear-drive motor. Being built for a powerful new SUV from CEER, this unit weighs just 132kg, instead of the Nevera’s 198kg.

The other was a much smaller package, possibly targeted at a performance coupé or perhaps even a very potent hot hatch, with a suitcase-sized 500bhp power pack weighing just 48kg.

Importance of “unique Rimac culture”

Pitarevic was poached last year by Mate Rimac from a top job in a big-scale manufacturing group, where he was managing 10,000 people in 22 factories around the world.

Asked what drew Bosnian-born, Germaneducated Pitarevic, at 36, to join what is a much smaller Croatian company still in its development phase, he said: “I’d heard about the unique Rimac culture of work and progress and that was very attractive and enough to get me started. Then when I joined, I found three more things I really liked.

“First, no one sends emails to get decisions. They communicate much faster than that. There’s a reluctance to waste time.

“Second, there’s a climate that always encourages innovation. If someone has a good idea, no one – last of all Mate Rimac – is going to stop them trying it.