GM’s Fairfax, Kansas plant to host automaker’s affordable EVs

General Motors (GM) has announced plans to develop and build an affordable next-gen electric vehicle (EV) at its Fairfax, Kansas, plant. While Chevy’s new Bolt EV is entering production by the end of the year at the same Kansas facility, it’s unclear whether the up-and-coming next-gen model is part of the Bolt family or a new lineup. GM’s president, Mark Reuss, said in October the 2027 Bolt EV’s “price isn’t final yet,” while adding “it [2027 Bolt EV] will be priced only slightly higher than the 2023 Bolt, which started at $28,795, and it will just be one member of a family on the Bolt, including an even lower cost option,” according to GM Authority.

The average transaction price (ATP) for a new EV in May was $57,734, Kelley Blue Book reports. Chevy’s 2027 Bolt will be North America’s first Ultium-based model with lithium iron phosphate (LFP) batteries, helping the model sell at lower prices than ones with nickel manganese cobalt batteries. Despite details on the 2027 Bolt remaining limited, its release around mid-2026 means that Chevy is likely months away from revealing the model.

GM

GM’s ambitious U.S. production plans are taking shape

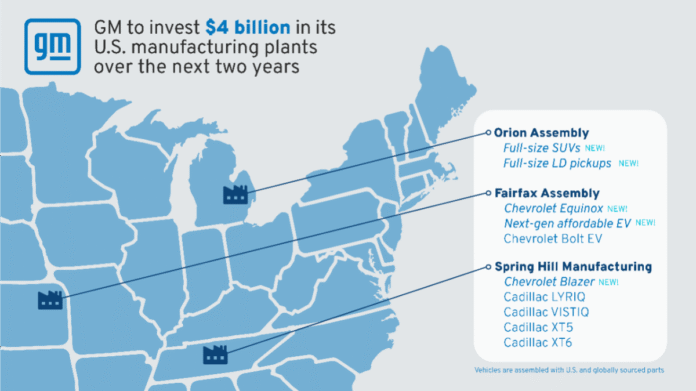

News of the affordable EV in development arrives after GM revealed plans to invest around $4 billion in U.S. production for gas-powered and electric models over the next two years. Domestic manufacturing investments should help GM mitigate the impacts of President Trump’s tariffs, which are projected to cost the automaker up to $5 billion in 2025. GM’s $4 billion investment will allow the company to manufacture over two million vehicles in the U.S. annually. In addition to making a next-gen affordable EV and the 2027 Chevy Bolt, GM’s Fairfax, Kansas plant will support the gas-powered Chevy Equinox’s production starting in mid-2027.

Equinox sales increased 30% year-over-year during Q1. Separate GM U.S. production facilities include Orion Assembly in Orion Township, Michigan, and Spring Hill Manufacturing in Spring Hill, Tennessee. Orion Assembly will take on gas-powered full-size SUVs and light-duty pickups, while Spring Hill Manufacturing will focus on the Chevy Blazer, the Cadillac LYRIQ and VISTIQ EVs, and the Cadillac XT5. GM’s Factory ZERO in Detroit-Hamtramck, Michigan, will handle the Chevy Silverado EV, GMC Sierra EV, Cadillac ESCALADE IQ, and GMC HUMMER EV pickup and SUV production.

Chevrolet

GM also confirmed plans last month to commercialize lithium manganese-rich (LMR) prismatic battery cells for future GM electric trucks and full-size SUVs. These cells will provide a 33% higher energy density compared to the best lithium iron phosphate (LFP)-based cells at a comparable cost. The new battery cells are expected to be a staple of the automaker’s electric truck lineup, with over 400 miles of available range, while optimizing savings over their high-nickel pack counterpart, which currently supplies segment-leading range.

Steve Fecht for General Motors

Final thoughts

Following GM’s most recent production announcement, the biggest question is whether its next-gen affordable EV will be part of the Chevy Bolt EV family or a new lineup. We also don’t know whether the 2027 Bolt EV, which is returning after a three-year hiatus, will revive its hatchback configuration or if the model will adopt crossover styling reminiscent of its EUV version. Still, it’s clear that GM’s manufacturing strategy is prioritizing affordability in the EV segment and cost mitigation amid tariff policies.